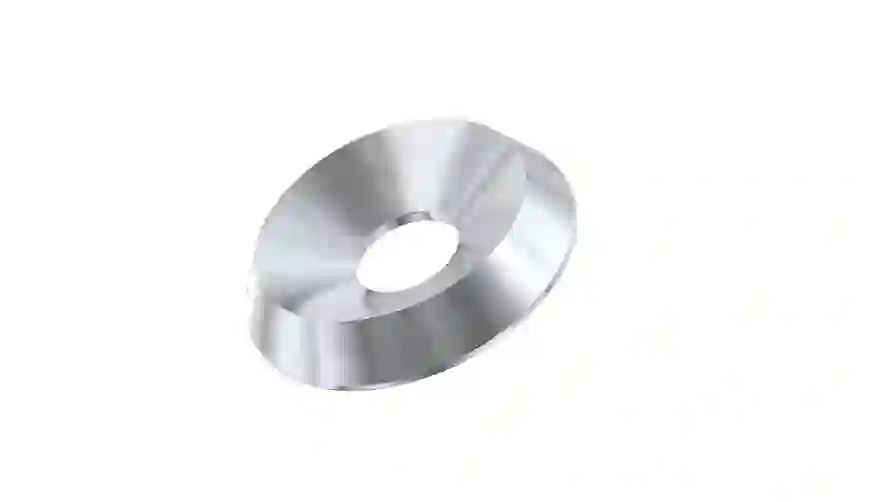

Leading the Way as a Countersunk Washer Supplier

Applications of Countersunk Washers.

- Woodworking

- Metalworking

- Construction Application

Countersunk Washer Material

| Materials | Grades |

|---|---|

| Stainless Steel | 304/H/L, 316, 317, 321, 347, 410, 447, 904L |

| Inconel | 600, 625, 800, 825 |

| Monel | 400, K500 |

| Hastelloy | C22, C276, B2, B3, X |

Countersunk Washer Mechanical Properties

Specifications of Countersunk Washer Excellence

Specifications | |

Countersunk Washer Size | M02 to M33, Custom Sizes |

Countersunk Washer Length | 3 mm to 200 mm |

Countersunk Washer Standard | DIN 125A, DIN 125B, DIN 127B, DIN 137B, DIN 6797A, DIN 6797J, ISO 7089, DIN 7980, DIN 127 B, IS 2016, ASTM F436M, ASME B18.13, ASME B18.21.1, ASME B18.22.1, ASME B18.23.1 |

Countersunk Washer Form | Hex, Threading, Square, Round as per Gauge Etc. |

Threads Configuration | ASME B1.1 2A/3A – 2B/3B Inch Unified Threads and B1.13M 6h-6G Metric Coarse Threads |

Certification | Dual Certified As per ASTM & ASME Codes |

Head Drive | Six-Lobe, Phillips, Phillips/Slot, Slotted etc |

Surface Coating | Ptfe Coated, Phosphate Coating, Teflon Coating, Zinc Coating, Hot Dipped Galvanizing Coating, Cadmium Coating, Xylon Coating |

Countersunk Washer Finishing | Coatings & Finishes: Self-Colour, Passivated, Bright Zinc Plated (BZP), Hot Dip Galvanised (HDG), Sherardized, special coatings like DACROMET Geometry and Mechanically Applied Coating, Dacroment, nickel plated, anodizing, plated zinc-nickel, Zinc (blue, black, yellow, white), black oxide |

Countersunk Washer Material Chemical Composition

| Countersunk Washer Material | Chemical Composition |

|---|---|

| Carbon Steel | Iron (Fe), Carbon (C), Manganese (Mn), Phosphorus (P), Sulfur (S), Silicon (Si) |

| Stainless Steel | Iron (Fe), Carbon (C), Chromium (Cr), Nickel (Ni), Molybdenum (Mo), and other alloying elements |

Countersunk Washer Types

Get in Touch

Our Products

Contact Info

- 0091 - 9004680120

- info@shivalikforge.com

- CIGRATEWALA BLDG., 364, S.V.P. ROAD, MUMBAI - 400 004